EUTEC™ FS/MF - Installation case study 21

(21) Application in motor manufacturing 2 (degreasing process)

| Aim of EUTEC installation | Removal of press oil during the cleaning of motor parts |

|---|---|

| Expected benefits of EUTEC installation | Improve quality of cleaning and prolong service life of cleaning fluid and rinse water |

| Cleaning target | Motor parts (motor housings) |

| Type of dirt/contaminant | Press oil, dust |

| Type of cleaner being used | Alkaline degreaser |

| Operating temperature of cleaner | 60℃ |

| Model of oil-water separator used (process flow rate) | TH-15 (15L/min) |

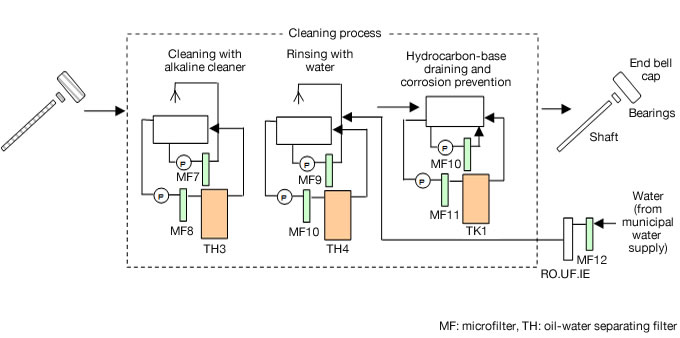

Degreasing process (shafts, end bells, bearings, brushes, etc.)

| Process | Filter usage point | Filter | Purpose of filter installation | Asahi Kasei filter series used |

|---|---|---|---|---|

| Pressing | Cleaning with alkaline cleaner | MF7 | Removal of foreign objects | KNP, AMWPP |

| MF8 | Removal of foreign objects, pre-filtering |

KNP, AMWPP | ||

| TH3 | Separation of oil | TH oil-water separator | ||

| Rinsing with water | MF9 | Removal of foreign objects | KNP, AMWPP | |

| MF10 | Removal of foreign objects, pre-filtering |

KNP, AMWPP | ||

| TH4 | Separation of oil | TH oil-water separator | ||

| Hydrocarbon-based draining and corrosion prevention | MF10 | Removal of foreign objects, pre-filtering |

KNP, AMWPP | |

| TK1 | Separation of oil | TK oil-water separator | ||

| MF11 | Removal of foreign objects | KNP, AMWPP | ||

| Generation of rinse water | MF6 | Removal of foreign objects from rinse water | KNA, KYS |

*Click here for more examples of cleaning-related installation flows.